Smart Electronics DC 12V 400RPM N20 Micro Gear Motor 16mm Shaft M4x55mm Screw Reducer with Gear Box

Smart Electronics DC 12V 400RPM N20 Micro Gear Motor 16mm Shaft M4x55mm Screw Reducer with Gear Box

Long shaft gear motor is a high quality gear motor. The gear motor adopts full metal structure including mental gear reducer with precise micro gear. This gear motor has large torque and small noise, can be used on electronic locks, intelligent model cars, robots, etc.

Long shaft gear motor is a high quality gear motor. The gear motor adopts full metal structure including

mental gear reducer with precise micro gear. This gear motor has large torque and small noise, can be

used on electronic locks, intelligent model cars, robots, etc.

Features:

Long output shaft, suitable for various low speed motor model such as precision robot, model aircraft.

Torque is big, all metal gears are durable and not easy to damage.

Small size, large torque and small current, with larger reduction ratio, the motor running more quiet.

Output shaft is a thread screw, can easily make a mobile transmission structure with a nut.

Can be used on electronic door locks, automatic door locks, intelligent robots, model vehicles, etc.

Specifications:

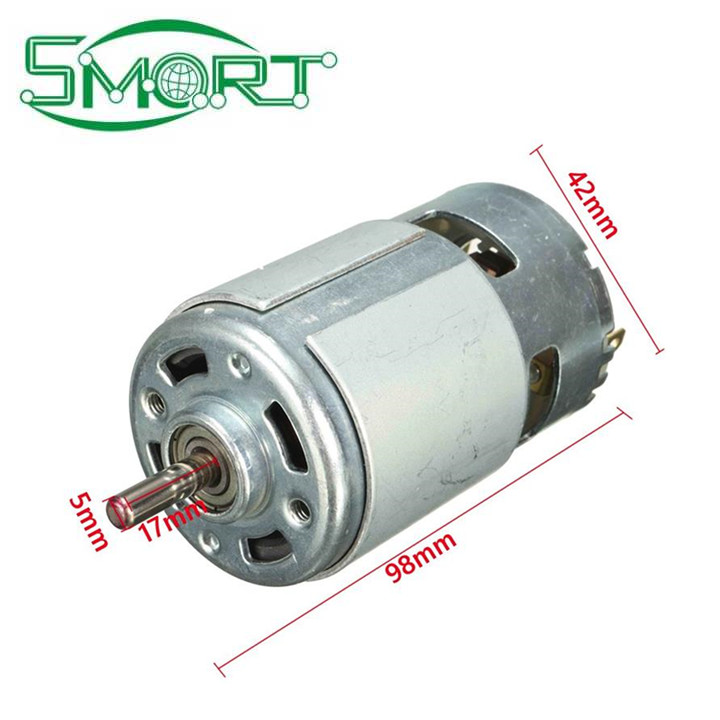

Motor Length: 16mm / 0.63"

Gear Box Length: 9mm / 0.35"

Cross Section Dimension: 12mm x 10mm / 0.47 x 0.39"

Output Shaft Length: 55mm / 2.16"

Output Shaft Diameter: M4

Rated Voltage: DC 12V

Rated Current: 0.17A

Rated Torque: 0.5 KG.CM

Original Speed: 20000RPM

Output Speed: 400RPM

Error: ± 10%

Weight: 18g(approx.)

Note:

1. When you use the motor, there must be no restraint. For example, the adhesive does not flow into

the bearing through the rotating shaft, which hinders the operation of the motor.

2. The rotation of the shaft may have the opposite effect on the life of the motor. In order to prolong

the life, please check whether your load is in accordance with the regulations, not overloaded, or the

end of the shaft is hung with obstacles.

3. Manufactured as an eccentric heavy-radiation load, detrimental to the life of the motor.

4. Do not store in high temperature or extreme humidity, and do not place it in corrosive gas, which

will reduce the motor effect.

5. Do not operate the motor in high temperature and humidity.

6. When soldering the motor terminals of the positive and negative poles of the power supply,

the temperature of the soldering iron should be 340 °C ± 40 °C, and the heating time should be less

than 3 seconds. Do not deform the plastic. During the work, let the solder point flow into the motor

or break the end of the wire. Decide the motor function.

7. Do not let the motor shaft get stuck. When the power is transmitted, the motor will overheat and

burn its accessories in a short time.

8. The quality cannot be guaranteed because the staff lacks the skills to make the motor meet the

instructions mentioned in the manual, or the surface judgment is obviously negligent.

9. Supply specified power, be sure to be within the measurable requirements.

10. Installation of pulleys or gears should not be aggravated when pressed.

11. When the motor is installed, the screw is too long, which will cause contact between the

motor itself and the rotor, which will affect the characteristics.