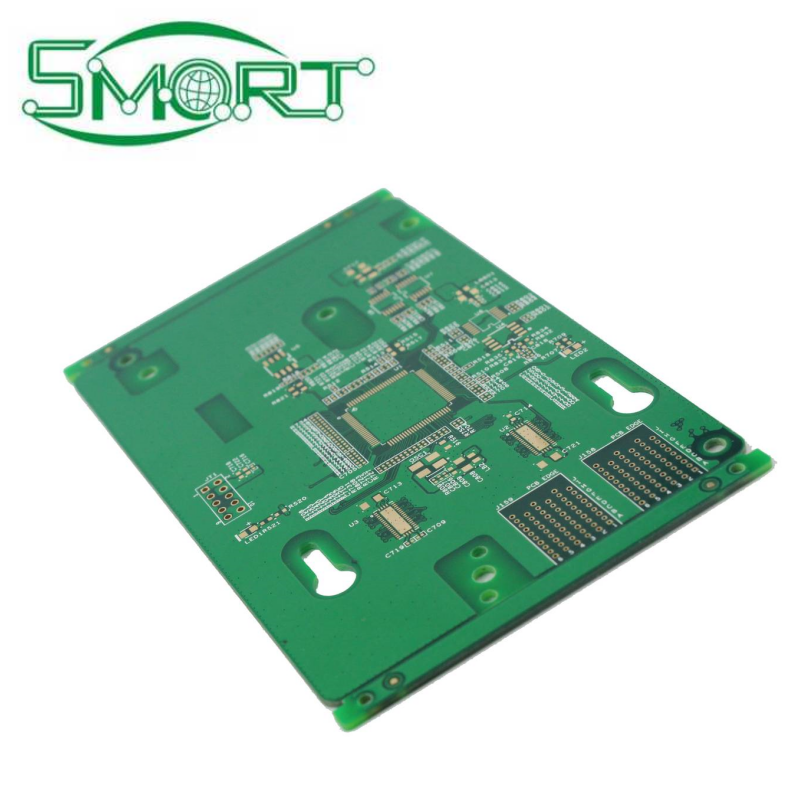

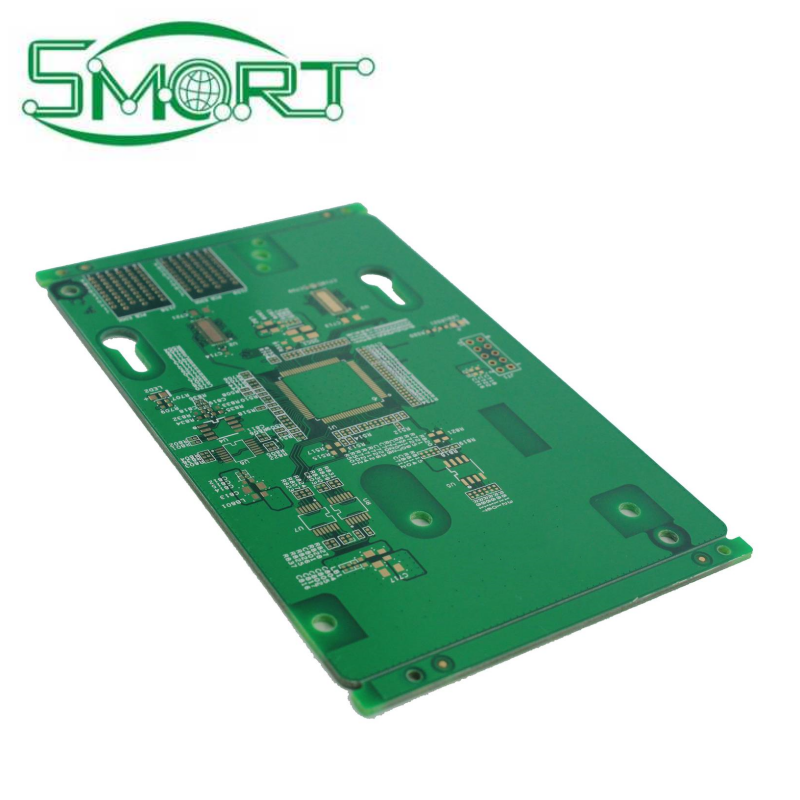

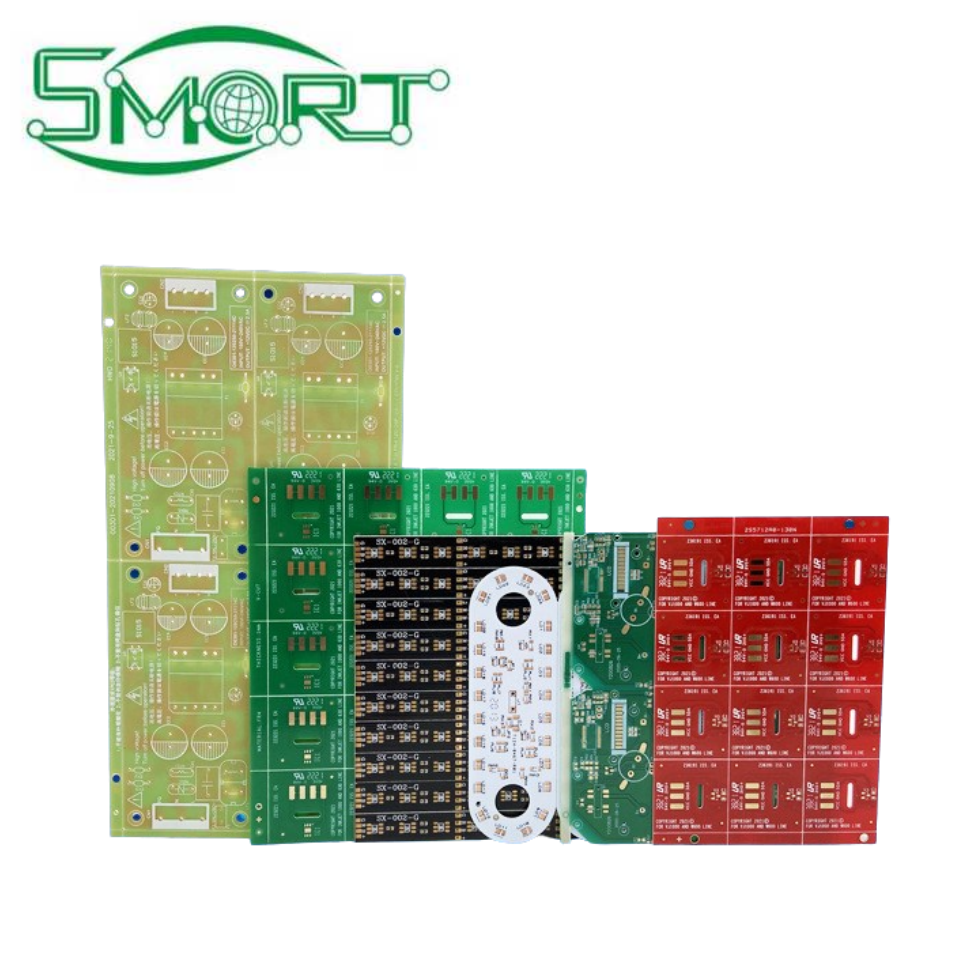

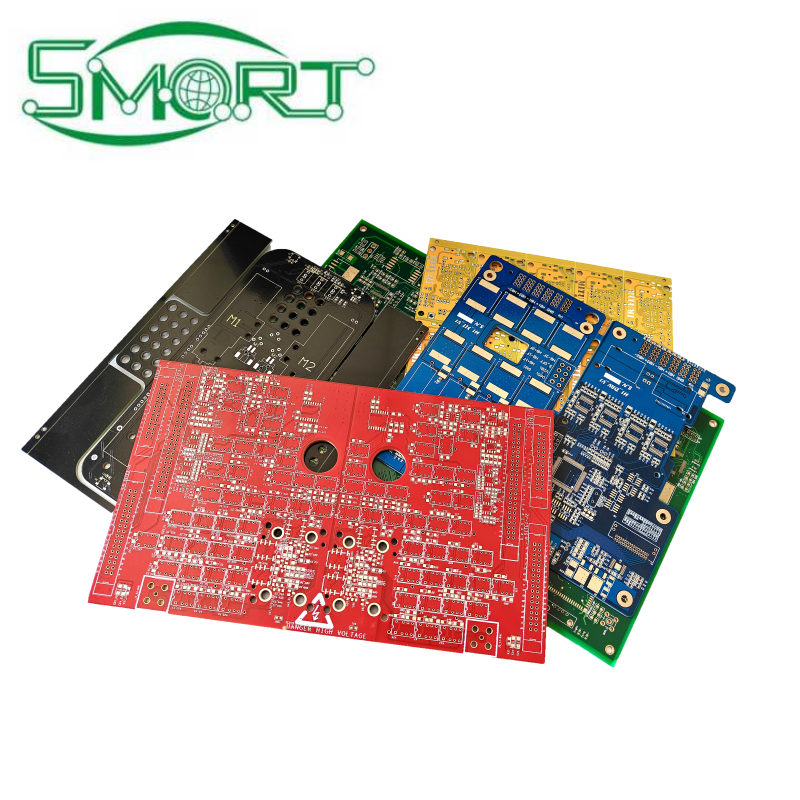

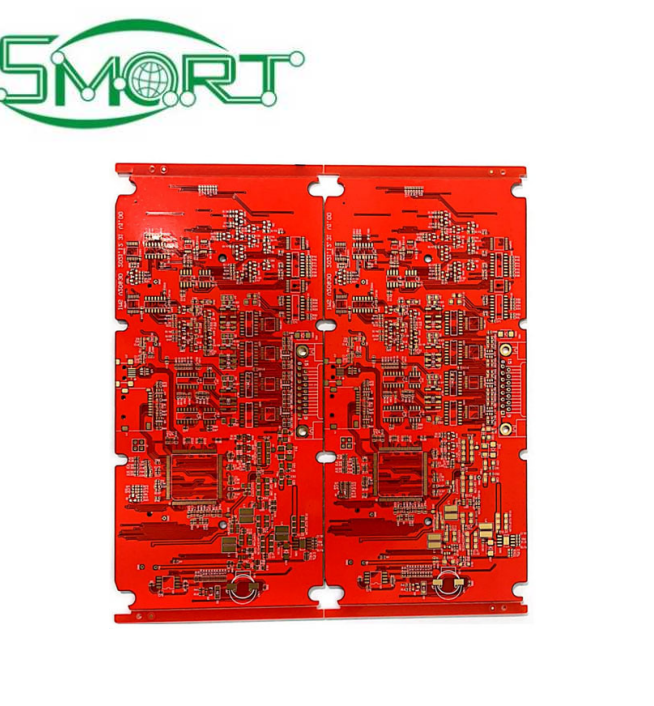

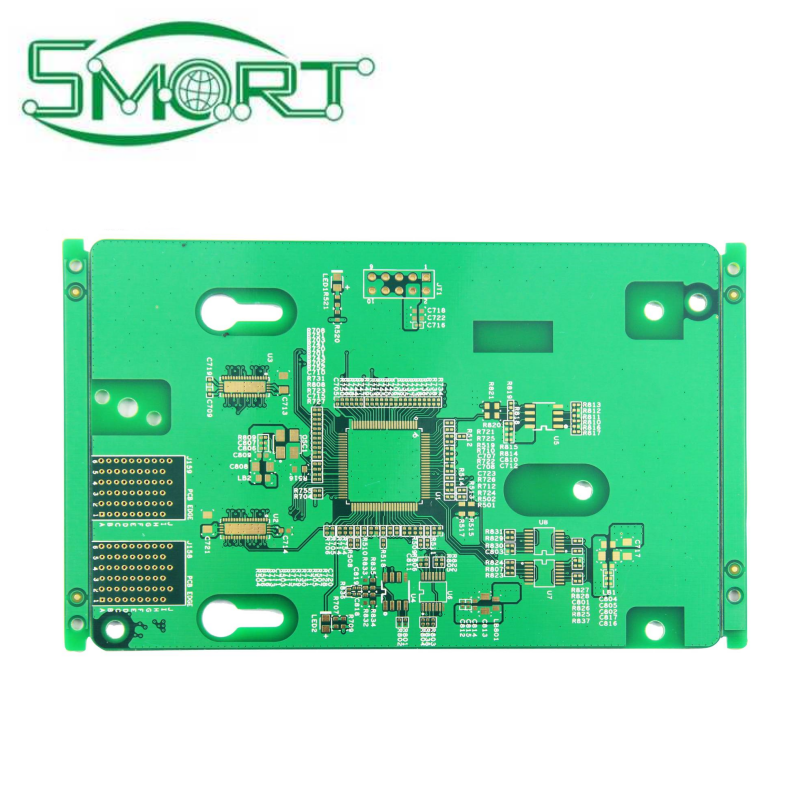

Smart Electronics 8 Layer Immersion Gold PCB OEM Custom Multilayer PCB Printed Circuit Boards Manufacturer

Smart Electronics 8 Layer Immersion Gold PCB OEM Custom Multilayer PCB Printed Circuit Boards Manufacturer

This PCB features eight layers of conductive materials and insulating substrates laminated together. The multiple layers

provide increased routing capacity and allow for more complex circuit designs. With eight layers, designers can separate

different signal types, power planes, and ground planes, reducing interference and improving signal integrity.

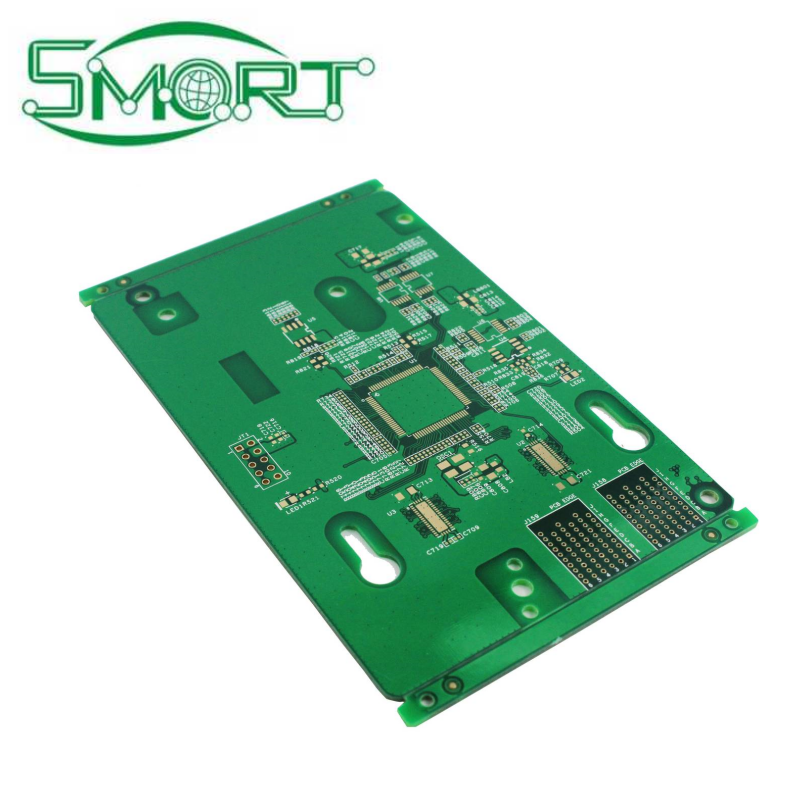

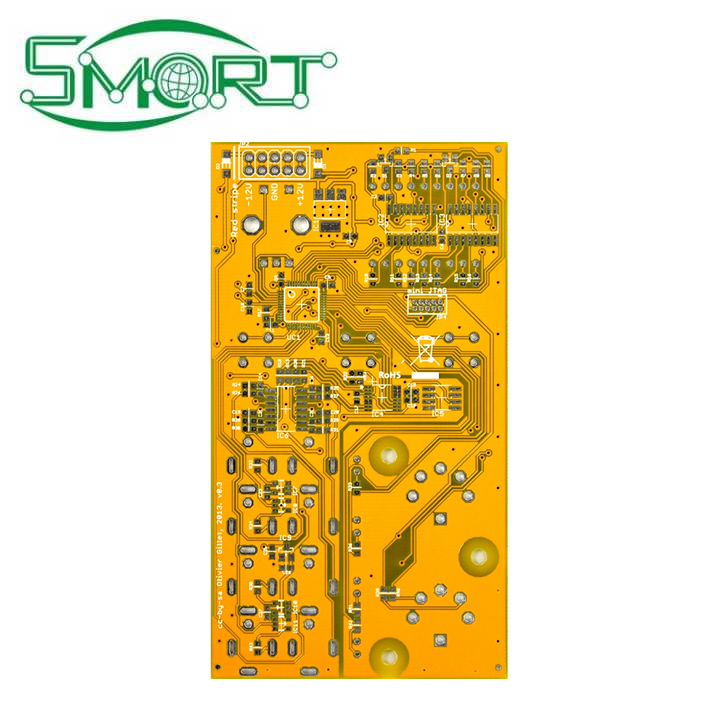

The immersion gold surface finish offers several advantages. Firstly, it provides excellent electrical conductivity, ensuring

reliable signal transmission and low contact resistance. This is crucial for high-frequency and high-speed applications

where signal quality is of utmost importance.

Immersion gold also offers excellent solderability. It allows for easy soldering of components and provides a stable and

reliable connection. The gold finish is resistant to oxidation, ensuring long-term reliability and durability.

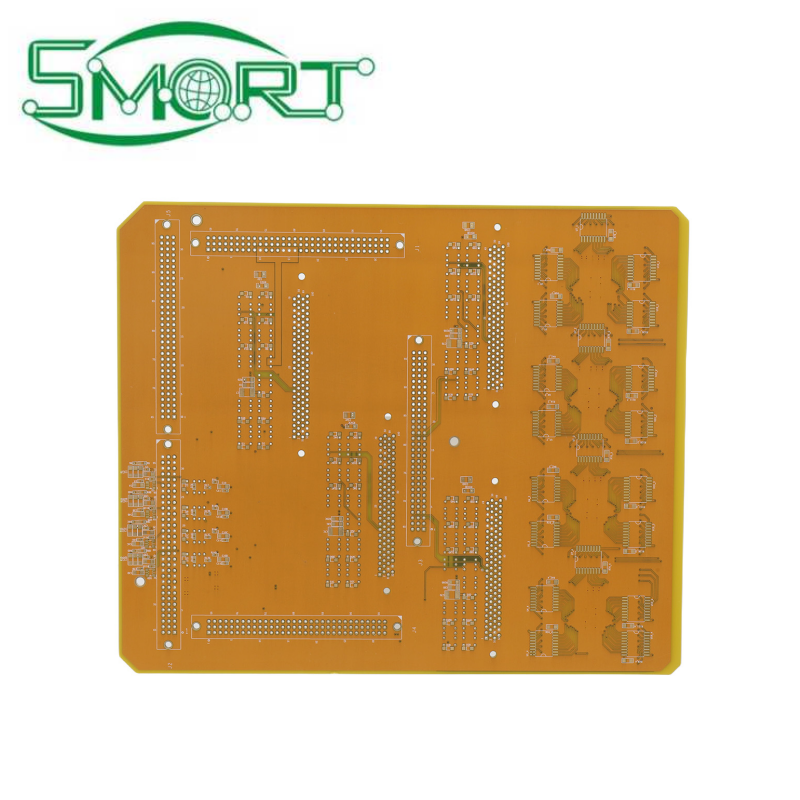

In addition, the immersion gold finish has a smooth and flat surface, which is beneficial for fine-pitch component

placement and high-density packaging. It reduces the risk of solder bridging and improves the overall quality of

the soldering process.

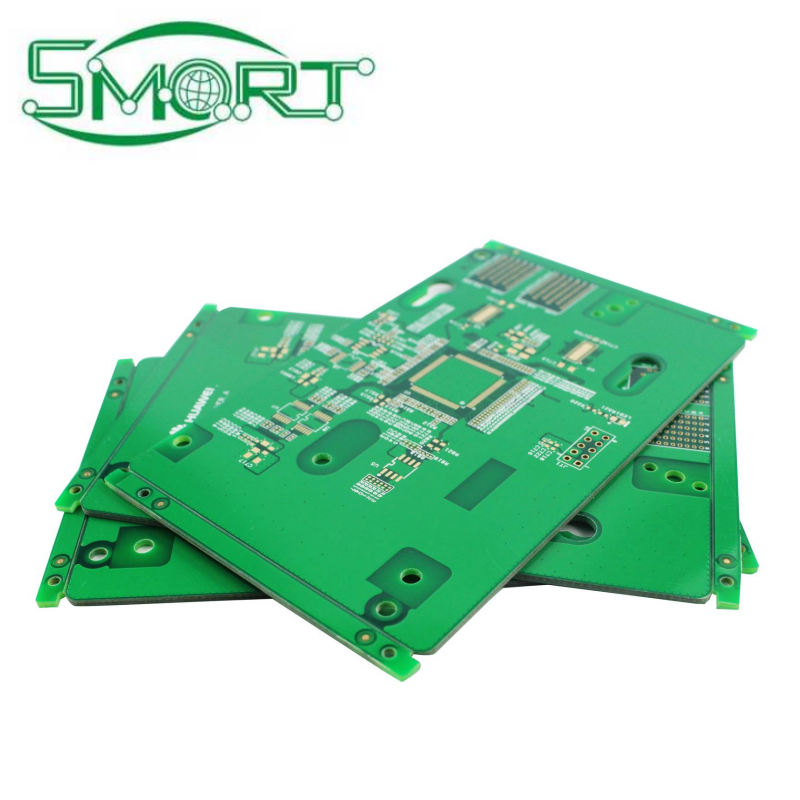

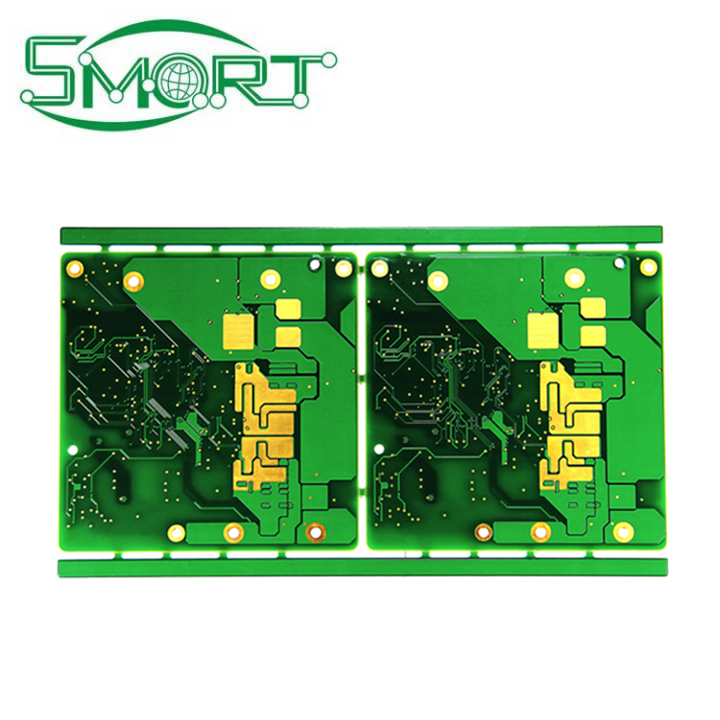

The manufacturing process of an 8-layer immersion gold PCB is complex and requires advanced technology and

expertise. Precise alignment and lamination of the layers, along with accurate drilling and plating processes, are

essential to ensure the quality and performance of the board.

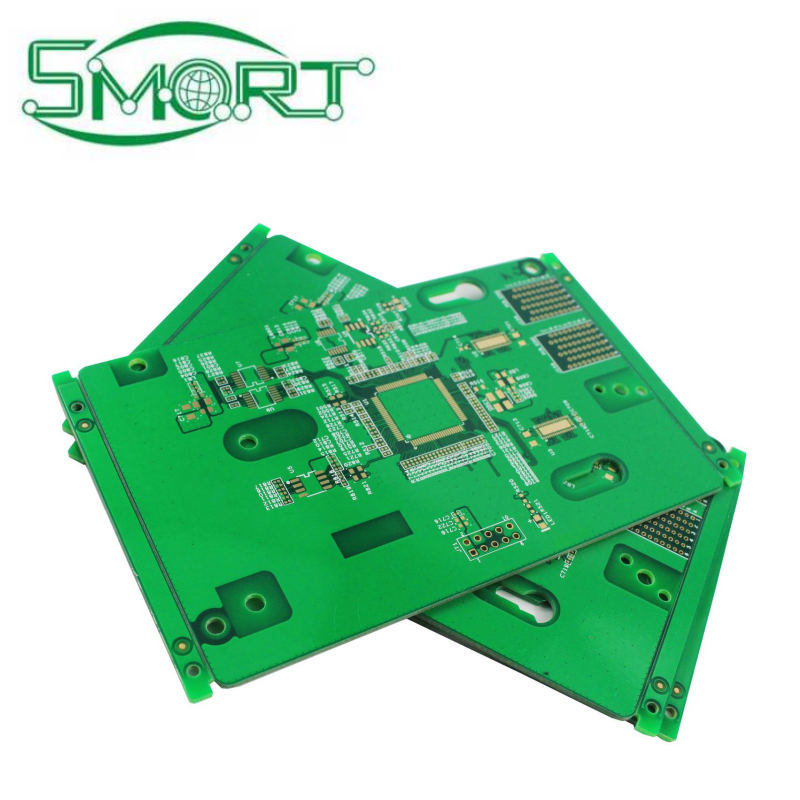

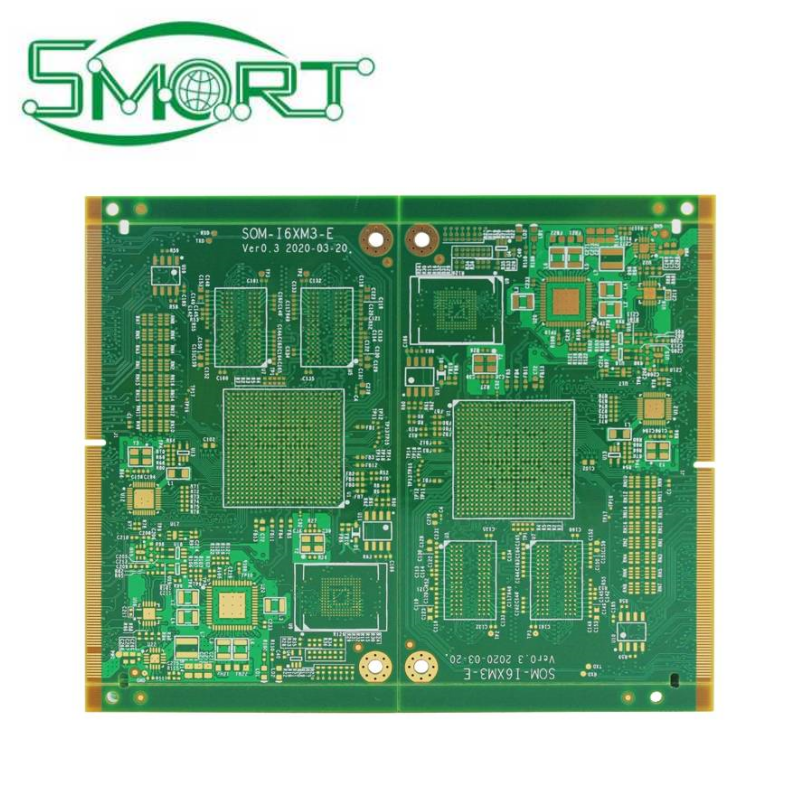

Overall, the 8-layer immersion gold PCB is a reliable and high-performance solution for a wide range of applications,

including telecommunications, computing, industrial control, and aerospace. Its advanced features and superior quality

make it an ideal choice for demanding electronic systems.